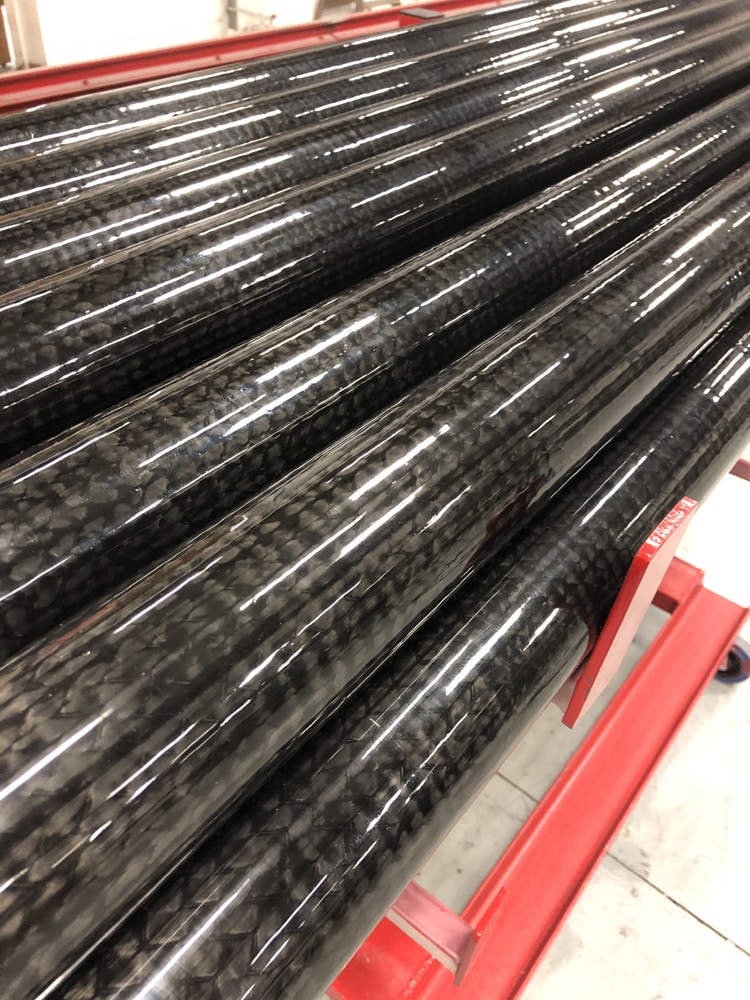

Carbon Fiber Tubing

The Best for Any Industry

Marine, Industrial, Aerospace, Military, and More!

We come across new and sometimes very unusual applications for our tubing every day. Our “Happy to Help” attitude has brought us a very diverse array of customers from performing arts to NASA. We focus on building advanced composite tubing, with the capability to deliver large diameters and extremely long lengths. Contact us to see what we can do for you.

Katy Perry’s Prismatic Tour

Katy Perry’s Prismatic Tour

Engineering and Design

Although we are not a full service composite engineering firm, we have helped many customers get their products from concept to reality. From custom end fittings and connections to structural laminate design and stress analysis, our staff can help you come up with a functional elegant design for whatever your product is. For engineering work in the “heavy lifting” category, we can refer you to a composite specific design firm we regularly work with.

Our ProcessCapabilities

4-Axis Continuous Fiber Braiding

4-Axis Continuous fiber braiding offers extremely durable tubing from approximately 1/2” ID up to 12” ID and continuous lengths from 10’ up to 60’. This tubing has relative high percentage of axial fibers and is mostly suited for compression, tension and bending applications.

Small Round Braided

Large Round Braided

Rectangle Braided

Square Braided

Roll Wrapping Pre-Preg

Roll wrapping pre-preg allows us to offer more off axis fibers for torsion or pressure applications. Roll wrapping lends itself to thinner wall applications because of the availability of very thin pre-preg material. This also allows for a more controlled OD surface without post machining. We typically build diameters ranging from .1” ID to 12” ID, and lengths from 6” up to 11’.

Machining and Assembly

Just outside of our walls a few miles down the road we have built a relationship with a CNC machine shop that has nearly dedicated their capabilities to machining carbon fiber parts. They often turn our bare tubes or blank plate into elaborate machined parts. We also have extensive experience in bonding and assembly of composites parts that have been proven in applications ranging from NASCAR to NEAR SPACE. We are happy to share our wealth of knowledge of adhesives or we can quote on finished assemblies.

Flat Stock

Flat carbon fiber plate from .125 up to .375” thick. Various laminate designs to get the most strength possible. Carbon fiber plates offer endless possibilities for fabrication and assembly.

Stock Tubing

We don’t really “stock” tubing. There are so many different wall thicknesses and fiber orientation options that most tubing is custom built for the application. What we do consider stock, is tubing sizes that we already have a mandrel for (tooling). After picking a mandrel, we will engineer a laminate and build the tubing to you specs. This can usually be accomplished in about a week. In some rare cases I may have tubing in stock for products we commonly build, so don’t be afraid to ask us.

Finish Coatings and Paint

We have two 40’ long paint rooms that are constantly full cycling parts through. We offer a variety of finished coatings including beautiful Yacht quality paint finishes, UV cured finish systems, High-wear ceramic infused coatings or even a paint prep process which takes a significant portion of the prep work out if you choose to do your own finish work.

No Coating

Clear painted

Ceramic Coating

Sizes and Sections

We offer many different sizes and shapes of carbon tubing to choose from. We have many round, square, rectangular, airfoil and oval sections available. Not all of our available sections are listed. We are always getting new sizes and shapes for custom projects. Please contact us to see if we have something that may work for you.

Section Drawings- No Coating

- Clear Painted

- Ceramic Coating

What they’re saying

Bare Tubing to Finished Products

In addition to unfinished / bare carbon fiber tubing, we can also provide many other post manufacturing services.

- Sanding painting / coating

- OD turning

- Centerless grinding

- Machining

- Hardware installation (end fittings, hardware, etc)

- Assembly

Applications

Our tubing has been used in a wide range of applications

- Light Aircraft

- Prototype Aircraft

- Aerospace

- Radar and GPS antennas

- Communication towers

- Stiffening and reinforcing beams

- Wind power

- Autonomous craft

- Unmanned vehicle capture booms

- Underwater equipment

- Telescope housing

- Large telescope truss tubing

- High Altitude Craft

- Robotic arms

- Transport beams

- Measurement devices

- Electronics housing

- Mining equipment

- Performance arts and production

- Oil and Gas down-hole applications

- Printing rollers and guides

- Truss Structures

- Security gates

- Photography and motion picture

- Energy generation

- Manufacturing beams

- Product distribution

- Medical equipment

- Solar Energy

- Fuel Cell housing